You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Violating a Princess!

- Thread starter SquirrellCook

- Start date

SquirrellCook

Forum Member

You are correct Trev, but remember I'm working in a housing estate. There is only so much you can get away with outside. As I've typed before the steel that would most benefit from shot blasting is impossible to get at without stripping of the body. Yes hot rolled hollow section mill scale will flake off in time, that's why I allowed it to rust a little. I've also used galvanised and Zintec, both of which should be etch primed. It was originally epoxy primed, but still corroded under it. It was also fully wax oiled and where the steam cleaner didn't reach it's still there.

Mucky has had it's entire sub-chassis replaced around 13 years ago and showing no signs of rot. Yes each year we cold wash it's bottom and touch up any suspect paintwork.

If I'd have had my way I'd have built a new one from a 6 series sprinter chassis bulkhead. Anita wouldn't pay for it.

Mucky has had it's entire sub-chassis replaced around 13 years ago and showing no signs of rot. Yes each year we cold wash it's bottom and touch up any suspect paintwork.

If I'd have had my way I'd have built a new one from a 6 series sprinter chassis bulkhead. Anita wouldn't pay for it.

SquirrellCook

Forum Member

Slow progress, but it is progress. Bags and air chambers removed to aid cleaning and painting. Structure has been added to have a gas locker on the left hand side and a home for the calorifier on the right hand side. The Gas locker will be panelled on the inside to help with the inevitable rough handling of the gas cylinders. The Calorifier home will just have celotex bonded into the frame.

Whilst I was under there glass fibre repairs were done to the wheel boxes. Coach operators run cheap tyres that blow out often it seems.

Insulation sheets. It looks like the standard thickness used with the expanded polystyrene was 40mm. So an easy replacement. To level the glass fibre roof I wanted a 20mm sheet so I could cut 40mm wide spacers to attempt to level the roof. I didn't like the idea of trying to cut 20mm slices of the 40mm. I don't really need the insulation at the moment, but the delivery costs make it sensible to buy all at once. All I wanted now was the 20mm. So all the insulation sheets turn up today. No 20mm!! substituted with 25mm!!

Whilst I was under there glass fibre repairs were done to the wheel boxes. Coach operators run cheap tyres that blow out often it seems.

Insulation sheets. It looks like the standard thickness used with the expanded polystyrene was 40mm. So an easy replacement. To level the glass fibre roof I wanted a 20mm sheet so I could cut 40mm wide spacers to attempt to level the roof. I didn't like the idea of trying to cut 20mm slices of the 40mm. I don't really need the insulation at the moment, but the delivery costs make it sensible to buy all at once. All I wanted now was the 20mm. So all the insulation sheets turn up today. No 20mm!! substituted with 25mm!!

SquirrellCook

Forum Member

Calorifier turned up today, so a test fit couldn't be resisted. It's going to be snug, but it'll be ok. Once installed any space around it will be stuffed with insulation.

Also a trial fit of a gas cylinder. Again snug for two cylinders, but it'll be ok. The access door will be on the outside. Unfortunately a bracing bar will cross the door opening. Something that will have to be lived with. The cooker will not be far away, so the gas pipe run will be short.

Also a trial fit of a gas cylinder. Again snug for two cylinders, but it'll be ok. The access door will be on the outside. Unfortunately a bracing bar will cross the door opening. Something that will have to be lived with. The cooker will not be far away, so the gas pipe run will be short.

SquirrellCook

Forum Member

Where practical I've been stuffing the roof with the 40mm PU insulation. Yes cutting the 20mm strips by hand. I bought an insulation hand saw, it works better than expected. Though hard work pushing it through thicker sections.

Whilst working on the roof I thought it was time for another Maxxfan. http://www.rainbow-conversions.co.u...deluxe-roof-vent-fan-with-remote-control.html It seems to be a popular product as I've not been able to find one at a sensible price, unless I want it in white.

Whilst working out what will fit where I purchased a cooker extractor. https://leisurelines.net/dometic-ck400-cooker-hood-5090-p.asp I don't think it came from these people, but it arrived broken. Not the end of the world, but they had no replacement stock.

I've not given it much thought, but overhead lockers need to be designed and made. (when will it ever be finished?)

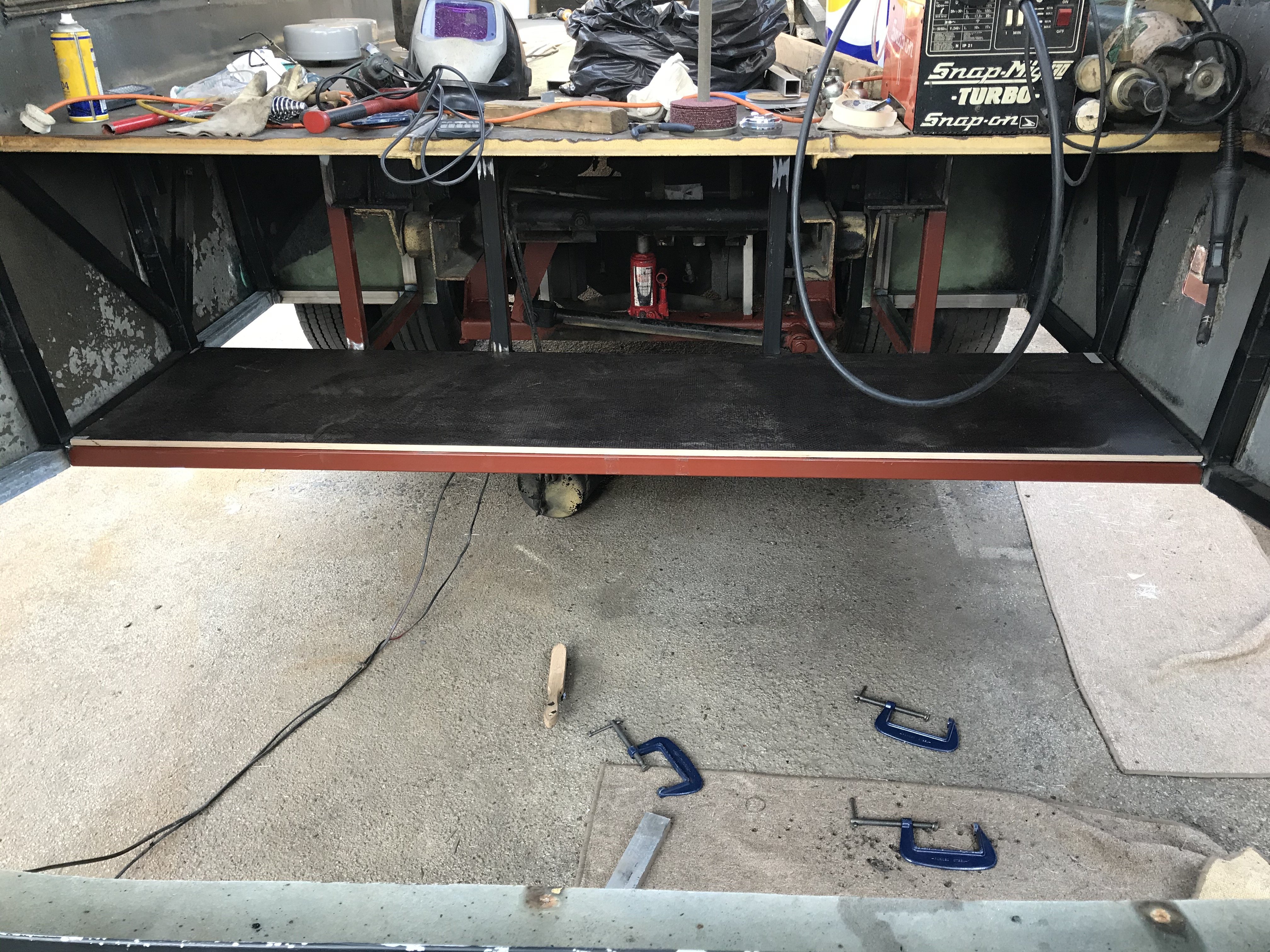

A couple of action shots of Anita fabricating the garage floor outer supports for me to weld in.

Whilst working on the roof I thought it was time for another Maxxfan. http://www.rainbow-conversions.co.u...deluxe-roof-vent-fan-with-remote-control.html It seems to be a popular product as I've not been able to find one at a sensible price, unless I want it in white.

Whilst working out what will fit where I purchased a cooker extractor. https://leisurelines.net/dometic-ck400-cooker-hood-5090-p.asp I don't think it came from these people, but it arrived broken. Not the end of the world, but they had no replacement stock.

I've not given it much thought, but overhead lockers need to be designed and made. (when will it ever be finished?)

A couple of action shots of Anita fabricating the garage floor outer supports for me to weld in.

Millie Master

Forum Member

That isn't the kind of piece of kit that you can buy from Toolstaion is it?

SquirrellCook

Forum Member

That isn't the kind of piece of kit that you can buy from Toolstaion is it?

Yes I find Anita really handy. Definitely not available at Toolstation.

BusBoy

Any more pics, I'm converting an 05, surprised at the state of the box section inside and how difficult it is to remove panels.

BusBoy

BusBoy

BusBoy

I think it's only the windscreen that's single glazed?Looks good,biggest problem will be the single glass windows losing heat and condensation,keep us up to date with picys,best of luck with build.

SquirrellCook

Forum Member

That's the best way. Strip all the panels off.

SquirrellCook

Forum Member

Mine was only single glazed.I think it's only the windscreen that's single glazed?

As you may have noticed it looks it was designed to have the condensation run behind the plastic trim panels.

BusBoy

How do you get the side skirt around the batteries off? I had to cut it in half. Also had to cut the cab as the panel below the windows was rivetted to the front edge of the box behind the cab.That's the best way. Strip all the panels off.

SquirrellCook

Forum Member

Have you discovered the appalling way the engine bay isn't sealed from the cab? You probably know better than me now, but the stainless panels appear to be attached with double sided foam sticky tape!Any more pics, I'm converting an 05, surprised at the state of the box section inside and how difficult it is to remove panels.

BusBoy

Hadn't noticed that yet, upgraded from an 811 thinking I wouldn't have to deal with rust, how wrong was I?Have you discovered the appalling way the engine bay isn't sealed from the cab? You probably know better than me now, but the stainless panels appear to be attached with double sided foam sticky tape!

SquirrellCook

Forum Member

I'd have drilled the rivets out, I'm yet to tackle the battery box metal work. Go slow and think about how they connect stuff. It will save you time in the end.How do you get the side skirt around the batteries off? I had to cut it in half. Also had to cut the cab as the panel below the windows was rivetted to the front edge of the box behind the cab.

BTW welcome to stupidity, or heroics

SquirrellCook

Forum Member

It will be worth it in the end. Just be careful about the steel you use and adding weight. Also the long runs can distort the body like you'd never imagine.Hadn't noticed that yet, upgraded from an 811 thinking I wouldn't have to deal with rust, how wrong was I?

BusBoy

Is it possible to contact you directly, can't see a way to message on this?I'd have drilled the rivets out, I'm yet to tackle the battery box metal work. Go slow and think about how they connect stuff. It will save you time in the end.

BTW welcome to stupidity, or heroics

Millie Master

Forum Member

Is it possible to contact you directly, can't see a way to message on this?

Unfortunately for you not as a free member, but once you become a full member then you can send other members a private message, or as it is termed on here, "start a conversation"

Phil