You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Violating a Princess!

- Thread starter SquirrellCook

- Start date

SquirrellCook

Forum Member

I've just done the balancing act! 18.9kg at the moment Dave, no idea what the weight would be in wood. All the drawers and worktop will add a bit.

SquirrellCook

Forum Member

To learn to stick weld it’s better to start with at least 6mm plate. A hobby welder would not be easy as the current will collapse as soon as you try to start an arc. It’s best to learn to gas weld first as it’s slow enough to see what’s going on. There lies the next problem, you need good eyesight.

I’m qualified in welding to the extent that I should either be inspecting welds or designing them. I also used to teach welding for a while. After the students had qualified I told them if the weld was important, let an expert do it. At least they would know if the so called expert was up to the job. A one year, 3 hours a week does not give you the experience.

I don’t have the dexterity to make the welds look pretty, but I know I get good root penetration and that’s the most important bit. BTW anyone claiming to be coded at welding is just bragging that they achieved a viable weld in a set condition, not that they are qualified.

I’m qualified in welding to the extent that I should either be inspecting welds or designing them. I also used to teach welding for a while. After the students had qualified I told them if the weld was important, let an expert do it. At least they would know if the so called expert was up to the job. A one year, 3 hours a week does not give you the experience.

I don’t have the dexterity to make the welds look pretty, but I know I get good root penetration and that’s the most important bit. BTW anyone claiming to be coded at welding is just bragging that they achieved a viable weld in a set condition, not that they are qualified.

Last edited:

SquirrellCook

Forum Member

Any way moving on from laying pigeon poo, the kitchen cabinet is back in Betty. Anita made a test drawer to prove the fit. Not so good, my countersunk screws hit the rollers. Try a slimmer drawer and see if that cures it. Once we have them slipping in and out pain free, we’ll brave making a dummy front to test drawer catch ideas.

I’ve used 25mm pu insulation to divide the drawers and put some more sticky foam insulation behind.

I’ve used 25mm pu insulation to divide the drawers and put some more sticky foam insulation behind.

st3v3

Forum Member

Anita made a test drawer to prove the fit. Not so good, my countersunk screws hit the rollers.

Don't make the drawers smaller, they'll not work properly or come out of the runners. Make the countersinks bigger

SquirrellCook

Forum Member

After spending a long time repairing holes, I decided to make some more. Yes I know that they are not vertical to each other, but I decided not to cut any structure out of the walls. One thing I did notice was that stainless steel screws don’t like biting into stainless steel sheet. Galvanised steel screws worked a treat. Another mistake made was not to measure from the same datum. So each vent is not horizontal to each other.

SquirrellCook

Forum Member

Anita got into repair mode and cleaned the rust scale and bad repairs from the front bumper. Steel treated and new glass fibre reinforcement.

SquirrellCook

Forum Member

Yes, I should have stuck to one trim line.Looks great.

Dd you line up each vent to be parallel to the closest trim line then? they look level to me.

wildebus

Forum Member

I don't know if that is so. You would have one vent that would have appeared askew as it was so close to a trim line but not aligned to it. I reckon you did the right thing even it you didn't mean toYes, I should have stuck to one trim line.

SquirrellCook

Forum Member

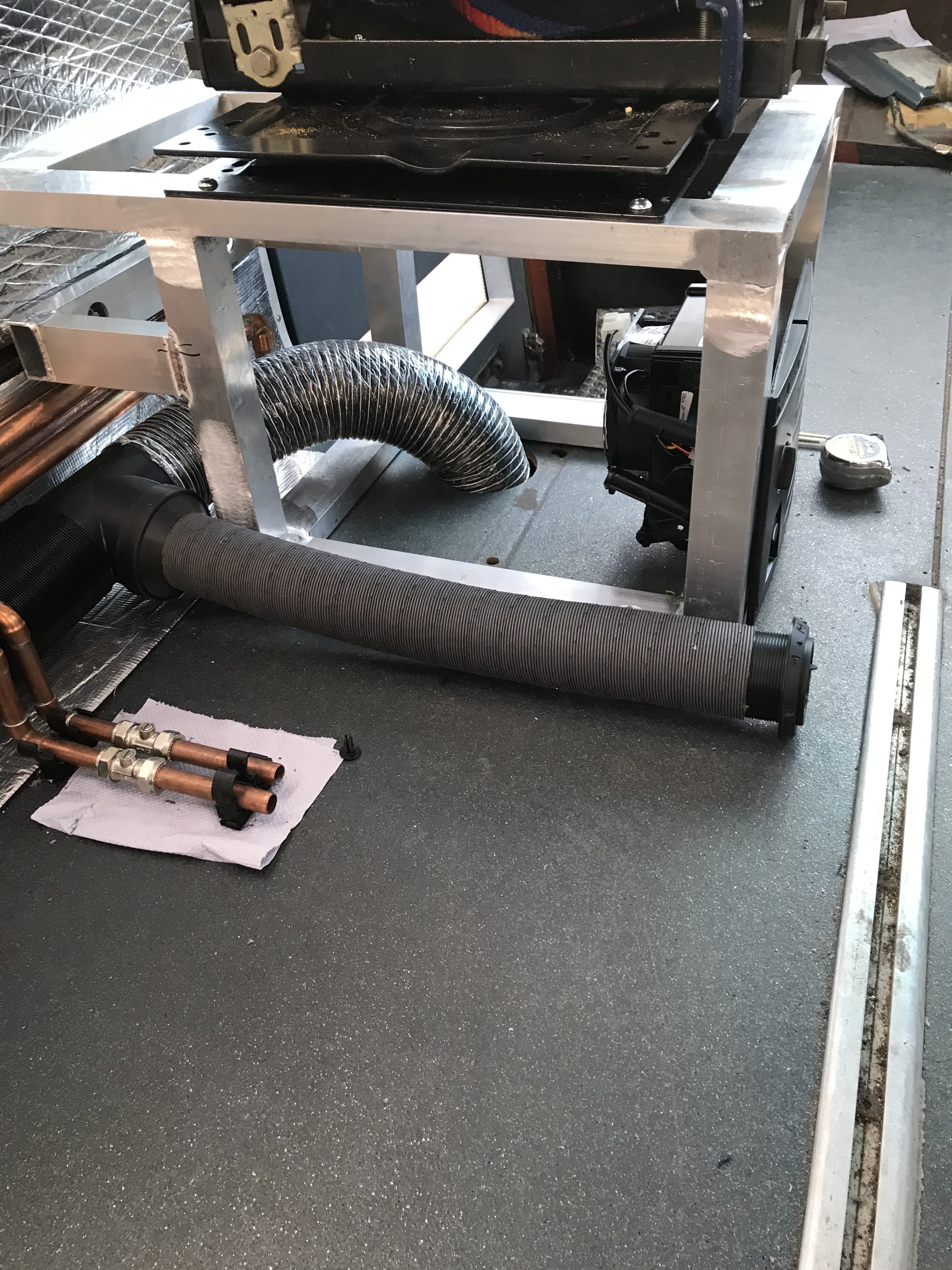

Still more plumbing! The M2 4kw eberspacher has now been purchased, so holes need to be made. Big holes as I’m using 90mm ducting. I was hoping to mount it side on under the step. This would have allowed clean easy runs for the intake and exhaust. Being forced to mount it to the bottom of the step I’ll have to make a top hat pedestal. This will allow the intake and exhaust pipes to bend away from the ground. Pictures on this later. Shown is the flexible hot air pipe escaping from the step and retuning back inside. And of course it fights for space with the water pipes. Another water heated fan is offered in place and I think it will stay there.

SquirrellCook

Forum Member

I should have been doing other things today, but one gremlin needed dealing with as it was calling my name. Also an opportunity arose, so it would be good to take care of that too.

Whilst boring holes yesterday and killing hole saws, I decided to do an easy one and add another bit of plumbing at the back. 92mm hole saw is supposed to be good for 90mm corrugated ducting. It’s not!! And the new hole saw didn’t like cutting the wooden floor.

So armed with a sharp half round file I thought I’d soon get the better of this. The hole laughed at me! Better weapons required. Industrial flexible shaft grinder with a 25mm spiral band. It’s an abrasive band mounted on a rubber holder. The grit is resin bonded. It didn’t take long to resize the hole. As I was under the main floor l cleaned and reshaped some steelwork that I had previously roughly cut with the plasma cutter.

Two Tee pieces joined with some ducting and I’m through the floor. I still have to make an adapter so that I can fit an air outlet to restrict the flow. I don’t want all the hot air heating the garage space. The other side will match, but that’s a job for another day.

So I hoped a more pleasant job. Two eberspacher controllers to mount. I was hoping for some kind of symmetry, but I thought I’d better look first. Caught you! There is a redundant handle under the moulding, there goes my symmetry.

Wiring can’t be hard? Pins in plugs, no problem. Even locked in place. Now I wondered why I had been given some pins for the sockets? The loom had incompatible connections on it! Then the new connectors need a suitable crimping pliers that I did not have. Not nice, but I made do. Better still the water eberspacher still works.

Duct from L/H rear heater

![IMG_0394[1].JPG IMG_0394[1].JPG](https://motorhomebuilder.com/attachments/img_0394-1-jpg.3547/)

From above heater

![IMG_0391[1].JPG IMG_0391[1].JPG](https://motorhomebuilder.com/attachments/img_0391-1-jpg.3549/)

Eberspacher controls, Water and Air

![IMG_0392[1].JPG IMG_0392[1].JPG](https://motorhomebuilder.com/attachments/img_0392-1-jpg.3550/)

Whilst boring holes yesterday and killing hole saws, I decided to do an easy one and add another bit of plumbing at the back. 92mm hole saw is supposed to be good for 90mm corrugated ducting. It’s not!! And the new hole saw didn’t like cutting the wooden floor.

So armed with a sharp half round file I thought I’d soon get the better of this. The hole laughed at me! Better weapons required. Industrial flexible shaft grinder with a 25mm spiral band. It’s an abrasive band mounted on a rubber holder. The grit is resin bonded. It didn’t take long to resize the hole. As I was under the main floor l cleaned and reshaped some steelwork that I had previously roughly cut with the plasma cutter.

Two Tee pieces joined with some ducting and I’m through the floor. I still have to make an adapter so that I can fit an air outlet to restrict the flow. I don’t want all the hot air heating the garage space. The other side will match, but that’s a job for another day.

So I hoped a more pleasant job. Two eberspacher controllers to mount. I was hoping for some kind of symmetry, but I thought I’d better look first. Caught you! There is a redundant handle under the moulding, there goes my symmetry.

Wiring can’t be hard? Pins in plugs, no problem. Even locked in place. Now I wondered why I had been given some pins for the sockets? The loom had incompatible connections on it! Then the new connectors need a suitable crimping pliers that I did not have. Not nice, but I made do. Better still the water eberspacher still works.

Duct from L/H rear heater

From above heater

Eberspacher controls, Water and Air

Last edited:

SquirrellCook

Forum Member

What a weekend, even with Anita’s help on Saturday very few of the planned jobs got completed.

Anita’s was tasked with modifying the angle section that mounts the curtains. The idea being to attach some z section aluminium to hide the curtain track and mount the over head lockers. Lots of holes to drill and mastering a violent air powered rivet gun. At least that job got completed.

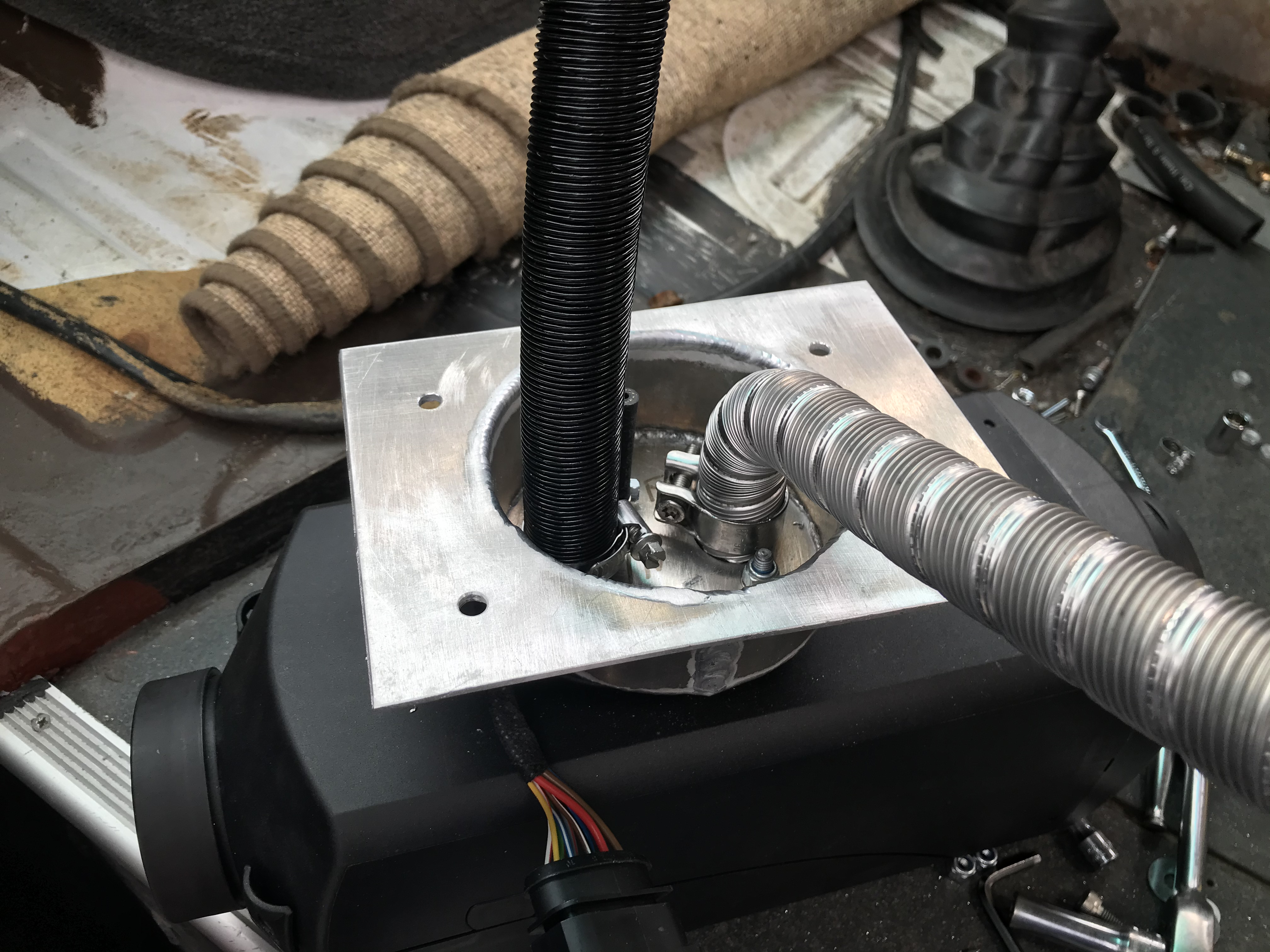

My first task was to mount and commission the M2 eberspacher. I should have taken more time, but I really don’t like sheet metal work. So a rough looking plinth was fabricated in twice the time a good man could have made a nice one.

Typical, the heater didn’t line up with the hole l cut in the step. So out with the flexible shaft grinder and enlarge the hole.

Routing the wiring loom. Even though I had more than enough cable I took the shorter direct route across the step. This will need some p clips later. A couple of hours later I’d managed to feed them though the wing panels. Stress was building and light was failing, time for home.

This morning full of enthusiasm, it wasn’t to last. Fuel and power needed to be routed along side the water eberspacher plumbing. Cable ties had been left loose to aid this. Still no fun as the back is on ramps and I was under the front.

Power connected and just the fuses to fit before it bursts into life. So fuses fitted and some kind of fault code pops up.

So continuity checks done, but still the unable to communicate code. The day ends early in frustration. I wonder if I was sold some duff stuff. Email Mellors in the morning.

Anita’s was tasked with modifying the angle section that mounts the curtains. The idea being to attach some z section aluminium to hide the curtain track and mount the over head lockers. Lots of holes to drill and mastering a violent air powered rivet gun. At least that job got completed.

My first task was to mount and commission the M2 eberspacher. I should have taken more time, but I really don’t like sheet metal work. So a rough looking plinth was fabricated in twice the time a good man could have made a nice one.

Typical, the heater didn’t line up with the hole l cut in the step. So out with the flexible shaft grinder and enlarge the hole.

Routing the wiring loom. Even though I had more than enough cable I took the shorter direct route across the step. This will need some p clips later. A couple of hours later I’d managed to feed them though the wing panels. Stress was building and light was failing, time for home.

This morning full of enthusiasm, it wasn’t to last. Fuel and power needed to be routed along side the water eberspacher plumbing. Cable ties had been left loose to aid this. Still no fun as the back is on ramps and I was under the front.

Power connected and just the fuses to fit before it bursts into life. So fuses fitted and some kind of fault code pops up.

So continuity checks done, but still the unable to communicate code. The day ends early in frustration. I wonder if I was sold some duff stuff. Email Mellors in the morning.

Last edited:

SquirrellCook

Forum Member

So finally made contact with Mellor's, The new eberspacher is going back. It seems it may not have the latest firmware. As they can't "flash" it, either a new ECU is required or a new unit. Could be a couple of months. I really don't want this to be a three year build

SquirrellCook

Forum Member

Had a call from Mellor’s today, it was an ECU compatible problem. A new one should be fitted in a week or so. Faster than expected, still lots of other jobs to do. Disasters at work with compatibility problems, so the next four days might get spent with this wreck.

Last edited:

SquirrellCook

Forum Member

So this weekend has been about “what can we finish?” Not strictly finish-able, we decided to tackle the overhead lockers. Sooner than expected we discovered that some of the material purchased for it was used on the sink cabinet. Though we were able to do enough for a trial fit of the cooker extraction unit. Whilst it was in place it made sense to temporarily wire it and check it’s functions. The shower fan was subjected to the same. More aluminium required, best work out what is required for the shower too.

I seem sealed some of the underside yesterday and Anita painted it today. Where ever you look there seems to be so much more to do.

I seem sealed some of the underside yesterday and Anita painted it today. Where ever you look there seems to be so much more to do.

SquirrellCook

Forum Member

I did say I’d type the truth, worts and all. It’s confession time!!

I’ve been getting very depressed with this build due to being unable to solve the indicator problem. No indicator, no MOT. Scrap Betty

Today in desperation I purchased from Mercedes a new body control module (fuse board) only to find after I installed it, no change.

Unbelievably I was so depressed I couldn’t bring myself to the British standard hammer attack.

So I set about swapping things out to isolate the fault. Still no fault found.

Next work backwards, what was I doing before loosing the indicators?

I’d just installed the water eberspacher, so was able to replace some panelling.

No damaged or pinched wiring

Next more wiring isolation, pull a plug and see what doesn’t work. Check indicator each time.

Fourth plug I pulled and the indicator worked!

I examined the wiring each side of the plug and socket. They didn’t match. I’D PUT IT IN THE WRONG HOLE!!

Problem solved and it was all my fault

I’ve been getting very depressed with this build due to being unable to solve the indicator problem. No indicator, no MOT. Scrap Betty

Today in desperation I purchased from Mercedes a new body control module (fuse board) only to find after I installed it, no change.

Unbelievably I was so depressed I couldn’t bring myself to the British standard hammer attack.

So I set about swapping things out to isolate the fault. Still no fault found.

Next work backwards, what was I doing before loosing the indicators?

I’d just installed the water eberspacher, so was able to replace some panelling.

No damaged or pinched wiring

Next more wiring isolation, pull a plug and see what doesn’t work. Check indicator each time.

Fourth plug I pulled and the indicator worked!

I examined the wiring each side of the plug and socket. They didn’t match. I’D PUT IT IN THE WRONG HOLE!!

Problem solved and it was all my fault