You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Violating a Princess!

- Thread starter SquirrellCook

- Start date

SquirrellCook

Forum Member

Thought I would muscle in and post something seeing as Mark always does the posting. Here he is cussing whilst doing the welding for our overhead storage lockers. Its a job he has been putting off but its taking shape

![IMG_1031[1].JPG IMG_1031[1].JPG](https://motorhomebuilder.com/attachments/img_1031-1-jpg.3761/)

SquirrellCook

Forum Member

As usually when I was supposed to be doing something else, I thought it was time to get some quotes on lining materials. Best measure up first. It was a bit nippy this morning, so fire up the water eberspacher to warm the place up. Water pump making horrible noises, what is going on? Turn off the heating and open the bonnet. Water pump is still screaming whilst going though it’s shut down procedure. Removing the header tank cap revels no water. Bugger the block has split! Removal of the dipstick shows correct oil level. Returning with a bucket of water it takes it all to fill it. Ok water leak! No antifreeze stains on the tarmac! You can’t be serious, did someone steal my antifreeze?

Any ways, bled the air out and tested the eberspacher. All good??

Back to doing what I shouldn’t have been doing in the first place and places a provisional order for my sheet timber.

Shortly after I’m informed that there is a global shortage and they can’t supply most of what I want.

Another manufacture and the same response! What a day!!

Any ways, bled the air out and tested the eberspacher. All good??

Back to doing what I shouldn’t have been doing in the first place and places a provisional order for my sheet timber.

Shortly after I’m informed that there is a global shortage and they can’t supply most of what I want.

Another manufacture and the same response! What a day!!

SquirrellCook

Forum Member

Progress. Anita has managed to secure some sheet materials for lining and other bits. The product I was after for the bulk of the lining was not available, so we settled for an inferior board.

The MII eberspacher has finally got an exhaust outlet, though still some tidying to do.

No sign of the air eberspacher from Mellors yet.

The MII eberspacher has finally got an exhaust outlet, though still some tidying to do.

No sign of the air eberspacher from Mellors yet.

Last edited:

SquirrellCook

Forum Member

This morning sheet material arrives from Latham's. All 0.26 tonnes of it. Now it's stuck in the door way until we have time, weather and space to work with it. 12mm for the garage floor and entrance step. 6mm for the inner shower room walls. 3.6mm for the roof and wall paneling.

![IMG_0455[1].JPG IMG_0455[1].JPG](https://motorhomebuilder.com/attachments/img_0455-1-jpg.3827/)

SquirrellCook

Forum Member

Just when you think you are winning.

The winning bit first. Murky developed a noisy water pump on it's M12 ebespacher. Not the end of the world as very easy to change. The £260 plus is not so nice. Webasto use the same pump and can be a little cheaper. Still unhappy with the price I found the very same pump at US boat shop. Even with shipping and taxes sub £200. A win I think.

The pump on Murky had been replaced with the new one for the Betty build, so poor old Betty gets the noisy one!

New pump fitted to Betty and all is good in the world, but where is the water going after half an hour of bleeding.

Anita has a look underneath and spots a small waterfall from the back of the engine

Engine cover off and removes a cover and a bracket to expose a naughty core plug.

In the fight to do this I drop Anita's phone I was using as a torch. It didn't hit the floor!

Can't see it from the top, so Anita does the back wiggle and goes underneath to find it resting on the exhaust.

Out comes a very Black Anita, me thinks she'll have to wash the bottom again.

Core plug removed and measured. Ordered a new one from Mercedes, let hope they are still in stock.

![IMG_0461[1].JPG IMG_0461[1].JPG](https://motorhomebuilder.com/attachments/img_0461-1-jpg.3828/)

![IMG_0467[1].JPG IMG_0467[1].JPG](https://motorhomebuilder.com/attachments/img_0467-1-jpg.3830/)

The winning bit first. Murky developed a noisy water pump on it's M12 ebespacher. Not the end of the world as very easy to change. The £260 plus is not so nice. Webasto use the same pump and can be a little cheaper. Still unhappy with the price I found the very same pump at US boat shop. Even with shipping and taxes sub £200. A win I think.

The pump on Murky had been replaced with the new one for the Betty build, so poor old Betty gets the noisy one!

New pump fitted to Betty and all is good in the world, but where is the water going after half an hour of bleeding.

Anita has a look underneath and spots a small waterfall from the back of the engine

Engine cover off and removes a cover and a bracket to expose a naughty core plug.

In the fight to do this I drop Anita's phone I was using as a torch. It didn't hit the floor!

Can't see it from the top, so Anita does the back wiggle and goes underneath to find it resting on the exhaust.

Out comes a very Black Anita, me thinks she'll have to wash the bottom again.

Core plug removed and measured. Ordered a new one from Mercedes, let hope they are still in stock.

Last edited:

SquirrellCook

Forum Member

Here we go with the next instalment of what seems to be a never ending saga.

Finally we have blown air heating, still to sort out the combustion side plumbing though. As I expected it bleeds too much hot air out of the back of the water heaters. Some lite weight flappy type valve required. I also found a nice foam air filter to stick on its nose.

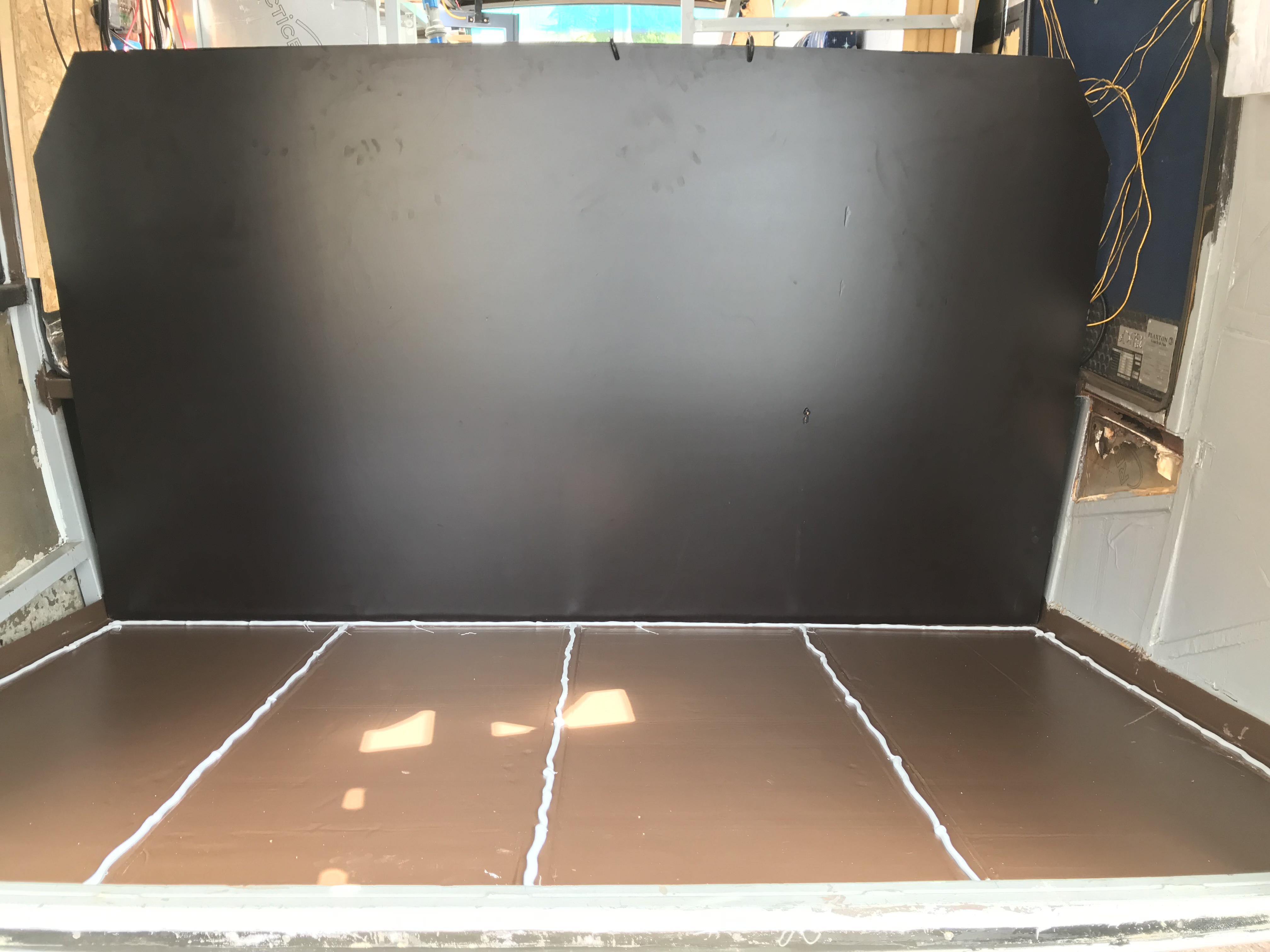

The next task was to cut and fit a new floor panel for the garage. The original was in two pieces, but I was convinced it could be done in one. Extra coats of paint were applied to the frame first to give it a cushion. Left to dry overnight. After doing a test fit, it was decided not to remove it again. A generous bead of pu mastic was applied to the steel work before refitting the panel. Then the labourius job of screwing it down. I will remove all the screws one by one and seal them with flexible epoxy.

Habitation next. This should be the most complicated wall panel. So worst first and it can only get better. With Anita stopping me being stupid I think we did quite well. I did mess up and ordered the wrong size panel clips so was only able to attach one panel. We did cut another. Each panel had its edges sanded before sealing the edges and backs with yacht varnish. Incorporated into the first panel was three fans for extracting heat from the fridge. Very small M4 fasteners, just the job for Anita.

Starting to look better inside. It was nice to have a warm workspace with the air heating working.

Finally we have blown air heating, still to sort out the combustion side plumbing though. As I expected it bleeds too much hot air out of the back of the water heaters. Some lite weight flappy type valve required. I also found a nice foam air filter to stick on its nose.

The next task was to cut and fit a new floor panel for the garage. The original was in two pieces, but I was convinced it could be done in one. Extra coats of paint were applied to the frame first to give it a cushion. Left to dry overnight. After doing a test fit, it was decided not to remove it again. A generous bead of pu mastic was applied to the steel work before refitting the panel. Then the labourius job of screwing it down. I will remove all the screws one by one and seal them with flexible epoxy.

Habitation next. This should be the most complicated wall panel. So worst first and it can only get better. With Anita stopping me being stupid I think we did quite well. I did mess up and ordered the wrong size panel clips so was only able to attach one panel. We did cut another. Each panel had its edges sanded before sealing the edges and backs with yacht varnish. Incorporated into the first panel was three fans for extracting heat from the fridge. Very small M4 fasteners, just the job for Anita.

Starting to look better inside. It was nice to have a warm workspace with the air heating working.

SquirrellCook

Forum Member

Keeping it simple. I have an air blown eberspacher connected to a length air hose. This runs from one end of the coach to the other. At the other end of the hose I have a water heated fan heater. This has been adapted to also blow into the same length of hose.

When the water heated heater is working some heat passes through the ebsepacher and warms the step area. This heating is normally used whilst driving. There are other air outlets along this hose. This setup seems to work as expected, though not tried on the road yet.

When parked up the air eberspacher will be used. The problem is and was expected, is that hot air is lost from the water heated fan heater at the back! Yes I could put a mechanical valve in place, but that's something else to remember. And no, a Pi controlled servo isn't going to happen.

Some kind of paper gravity controlled flap was my first idea, but I'm not that clever. So a polyurethane rubber flap was made. The pictures show the first test. Then the test with the eberspacher working. Very little heat being lost. Finally the water heated fan heater working. You can see the green rubber conforming to the translucent adapter. BTW the water heated fan heaters are mounted in the garage area.

![IMG_0484[1].JPG IMG_0484[1].JPG](https://motorhomebuilder.com/attachments/img_0484-1-jpg.3896/)

![IMG_0485[1].JPG IMG_0485[1].JPG](https://motorhomebuilder.com/attachments/img_0485-1-jpg.3897/)

![IMG_0486[1].JPG IMG_0486[1].JPG](https://motorhomebuilder.com/attachments/img_0486-1-jpg.3898/)

When the water heated heater is working some heat passes through the ebsepacher and warms the step area. This heating is normally used whilst driving. There are other air outlets along this hose. This setup seems to work as expected, though not tried on the road yet.

When parked up the air eberspacher will be used. The problem is and was expected, is that hot air is lost from the water heated fan heater at the back! Yes I could put a mechanical valve in place, but that's something else to remember. And no, a Pi controlled servo isn't going to happen.

Some kind of paper gravity controlled flap was my first idea, but I'm not that clever. So a polyurethane rubber flap was made. The pictures show the first test. Then the test with the eberspacher working. Very little heat being lost. Finally the water heated fan heater working. You can see the green rubber conforming to the translucent adapter. BTW the water heated fan heaters are mounted in the garage area.

SquirrellCook

Forum Member

Time to step up to another challenge. I’ve been putting this off for a while, but I don’t know why. A new step is required as the original is rotting. One of the pains being is that it also has to be a removable cover for the eberspacher. The eberspacher has a washable foam filter, so once in a while it would be best to clean it. I’ve also to install an entrance light and door switch. The original lamp was horrible, so I hope to do better. Finding the wiring will be fun as it was part of the air door system, I’ve removed all that. Any ways a couple of progress pictures.

SquirrellCook

Forum Member

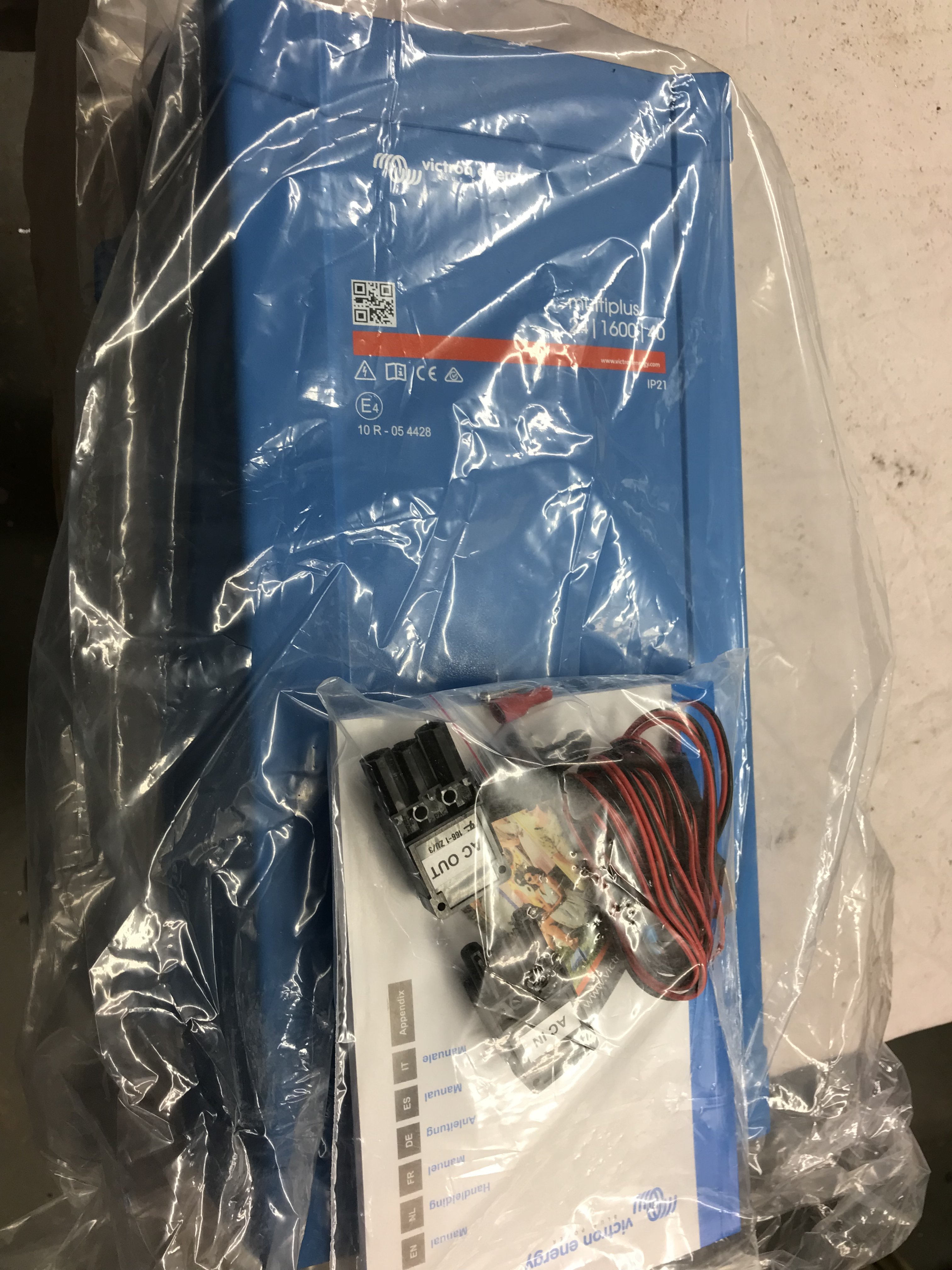

A big blue box turned up in the post yesterday.

SquirrellCook

Forum Member

A few more additions to the electrical cupboard. Hopefully I'll be able to shoehorn some relays into the consumer unit. Yes I know the yellow cable is too small, another reason a lack of bits stopped play.

![IMG_0504[1].JPG IMG_0504[1].JPG](https://motorhomebuilder.com/attachments/img_0504-1-jpg.4027/)

Millie Master

Forum Member

A few more additions to the electrical cupboard. Hopefully I'll be able to shoehorn some relays into the consumer unit. Yes I know the yellow cable is too small, another reason a lack of bits stopped play.

A very tidy job, and at least you know one of the cables needs beefing up a bit

Phil

SquirrellCook

Forum Member

1.5mmsq is actually supposed to be up to the job, but I'll go to 2.5mmsq.A very tidy job, and at least you know one of the cables needs beefing up a bit

Phil

wildebus

Forum Member

For that length of cable I really would't worry1.5mmsq is actually supposed to be up to the job, but I'll go to 2.5mmsq.

(I'd be replacing the L and N connection cables though with fatter ones (they do seem to be in a funny position as well?))

SquirrellCook

Forum Member

As I’m going to have to buy 50mtrs of 2.5mmsq, I’ll do the lot in it. No I haven’t connected live to neutral lol.For that length of cable I really would't worry1.5mm2 is good for something like 15.95A and the multiplus has a 16A limit.

(I'd be replacing the L and N connection cables though with fatter ones (they do seem to be in a funny position as well?))

SquirrellCook

Forum Member

Cerbo time soon, but I noticed a mistake in my design. All the Cerbo connections are from the sides.  I'm hoping if I elevate it, I can move it more towards the DC supply fuses that have now been lowered due to a forgotten isolator switch being added to the positive DC supply.

I'm hoping if I elevate it, I can move it more towards the DC supply fuses that have now been lowered due to a forgotten isolator switch being added to the positive DC supply.

![IMG_0554[1].JPG IMG_0554[1].JPG](https://motorhomebuilder.com/attachments/img_0554-1-jpg.4194/)

wildebus

Forum Member

That is very neat indeed

I have just this morning disconnected just about EVERYTHING in my installation to redo. Your cabling is putting mine to shame! (I would post a pic of mine but it would be X-rated for Horror ) It's all going to be connected the same again, but look a lot tidier and look more logical now the setup is virtually final (still waiting on my custom programmable VSDR-200 (200A Voltage Sensing Disconnect Relay) as the final piece for the Hybrid Battery but that should be fairly out the way from the rest anyway - hopefully will be programmed and tested in the next week ready to ship to me)

) It's all going to be connected the same again, but look a lot tidier and look more logical now the setup is virtually final (still waiting on my custom programmable VSDR-200 (200A Voltage Sensing Disconnect Relay) as the final piece for the Hybrid Battery but that should be fairly out the way from the rest anyway - hopefully will be programmed and tested in the next week ready to ship to me)

I have just this morning disconnected just about EVERYTHING in my installation to redo. Your cabling is putting mine to shame! (I would post a pic of mine but it would be X-rated for Horror

SquirrellCook

Forum Member

It just makes a handy terminal post.PPS. Is there a particular reason why you are fusing the -ve connection to the Midi Fusebox?