SquirrellCook

Forum Member

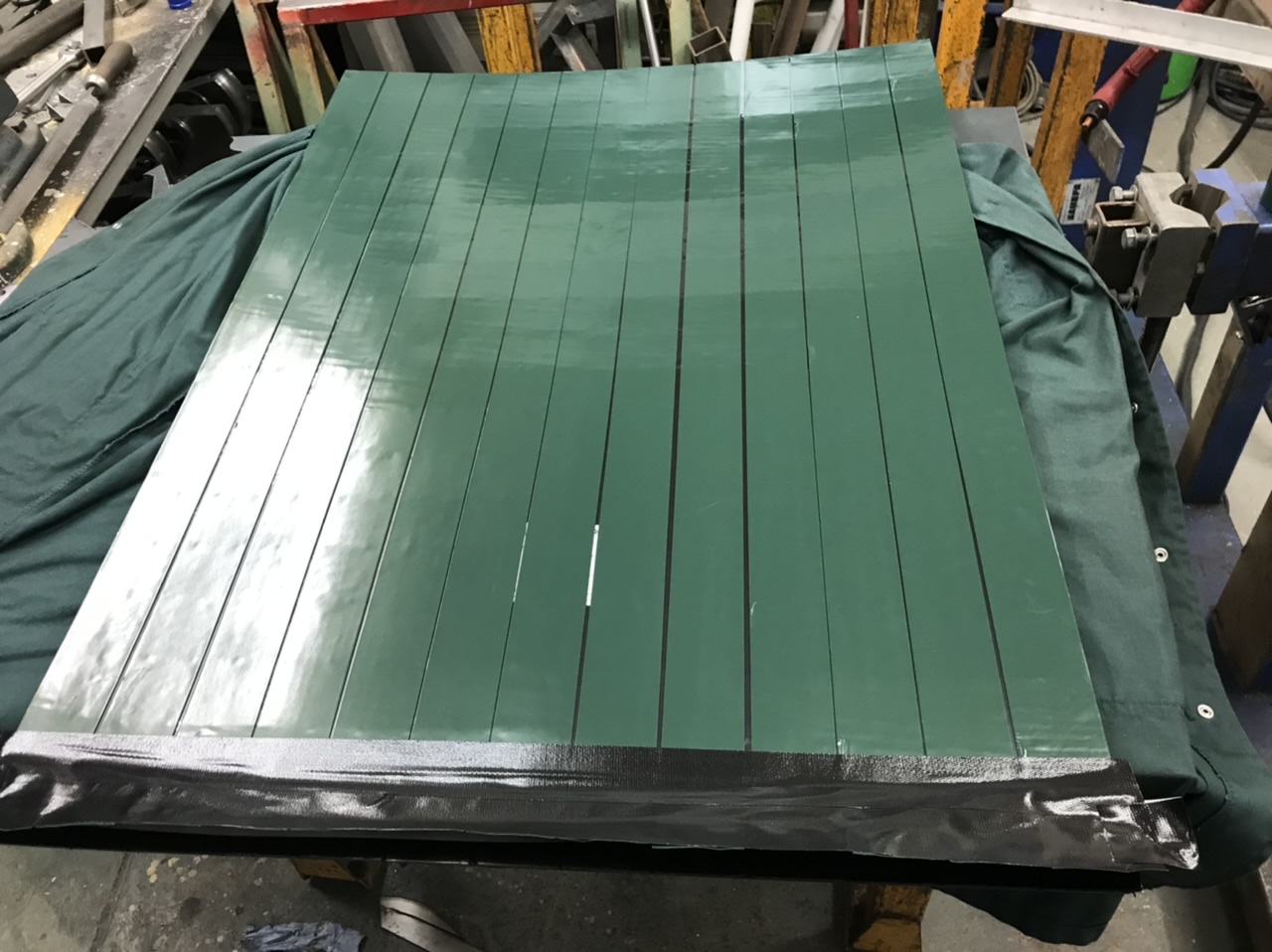

A touch more progress over the last couple of days. As the top coating of the roof was finished I was able to fit the last miasol panel. Extra space was left between these two for the shower fan and solar panel junction boxes.

I had some other solar panels to fill the last remaining space. The problem being that these panels were not self adhesive. I used double sided foam tape to coat the back of them being careful not to stretch the tape. The next problem was to join all the backing tape so that it could all be pulled away in one.

Put a couple of old batteries in the back and temporarily wired in the two new Victron solar controllers. Low and behold they do work as a pair looking after the same battery bank.

I had some other solar panels to fill the last remaining space. The problem being that these panels were not self adhesive. I used double sided foam tape to coat the back of them being careful not to stretch the tape. The next problem was to join all the backing tape so that it could all be pulled away in one.

Put a couple of old batteries in the back and temporarily wired in the two new Victron solar controllers. Low and behold they do work as a pair looking after the same battery bank.