wildebus

Forum Member

I mentioned I would be adapting a vehicles lesiure electrics from 12V to 24V .... Well today was the Day

The van in question was a 7.5t Horsebox on a 4,5l Mann Chassis and owned by Asterix from the Motorhomer.com Forum. The following is what was done, the pros and cons of 12V vs 24V and the cost implications of the change.

Changing the battery bank itself from a pair of 12V in Parallel to a pair of 12V in series was straightfoward and needed minimal parts.

Summary by system area:

1) Split Charge system

The existing system was a Redarc B2B/MPPT Controller, but this had failed.

12V Option. Fit another B2B Charger.

24V Option. Fit a VSR.

2) Solar System

The existing 660W (800W potential) Bifacial PV Array had connected to a Redarc B2B/MPPT Controller, but this had failed so an replacement was required.

12V Option. Fit an MPPT Controller capable of at least 50A and potentially 70A.

24V Option. Fit an MPPT Controller capable of at least 25A and potentially 35A.

3) Inverter

There was an existing 24V 1600W Modified Sine Wave Inverter that came with the Horsebox. This was servicable and a good brand (Waeco).

4) 12V Leisure Electrics

There was the various array of 12V Electrics to be serviced - Fridge, Lights, etc.

Costs of going 24V:

Using a VSR instead of a B2B provides a saving of approximately £200.

The 24V system means a Victron 100/30 is suitable. a 12V System would require at least a 100/50 or even a 150/60 in the Victron range. Using the 100/30 on a 24V system provides a saving of approximately £100 over the 100/50 on a 12V system whilst also providing more capability.

Using the existing 24V Inverter instead of purchasing an equivalent spec 12V Inverter provides a saving of around £200.

Needing to fit a DC-DC Converter suitable to support a Compressor Fit is a cost of around £130

Not needing to buy a device to allow the Starter Battery to charge from EHU and Solar would be a cost saving of around £60

Summary:

Updates and Purchasing Products were required whichever route was taken, but taking the 24V route meant a saving of over £400.

Clearly some of the saving was down to already having a 24V inverter.

The downside to the charging compromise of using a VSR instead of a B2B is mitigated by having a quality Smart MPPT Controller and a decent PV array to 'take up the baton' plus the benefit of getting the same Smart Charging available to the Starter Battery.

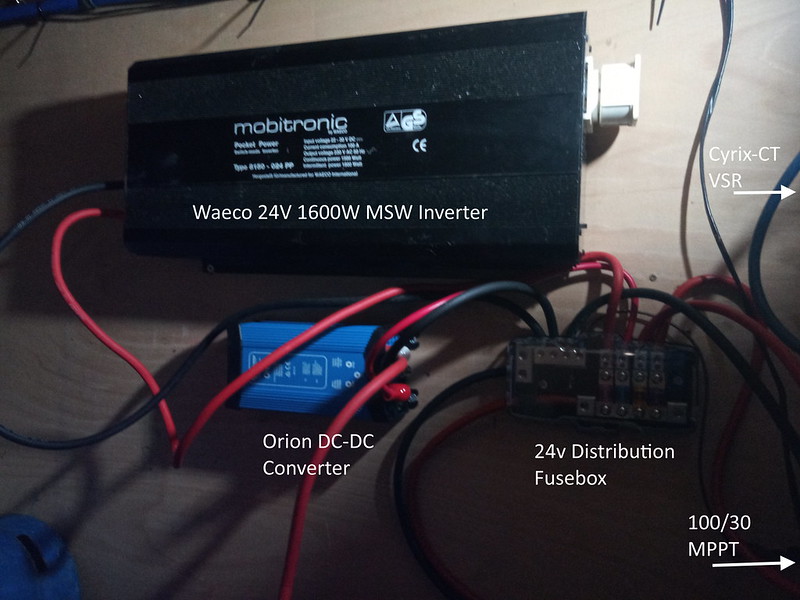

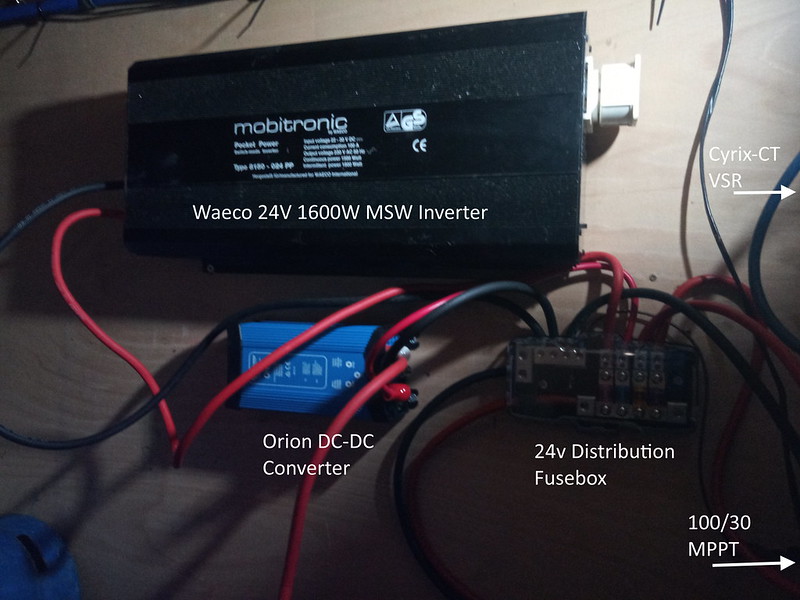

System following installation (but before cable tidying & clipping)

Horsebox Systems by David, on Flickr

(Sorry for poor pic. Didn't notice until too late to take another)

The van in question was a 7.5t Horsebox on a 4,5l Mann Chassis and owned by Asterix from the Motorhomer.com Forum. The following is what was done, the pros and cons of 12V vs 24V and the cost implications of the change.

Changing the battery bank itself from a pair of 12V in Parallel to a pair of 12V in series was straightfoward and needed minimal parts.

Summary by system area:

1) Split Charge system

The existing system was a Redarc B2B/MPPT Controller, but this had failed.

12V Option. Fit another B2B Charger.

24V Option. Fit a VSR.

| Voltage | Pros | Cons |

| 12V System | Better Charging Profile | Higher Cost |

| 24V System | Lower Cost Allows Starter Battery to charge from Leisure Battery charging systems (Solar, EHU) | Will not charge Battery to full extent due to Alternator voltage limitations. Needs Heavier Cable. |

2) Solar System

The existing 660W (800W potential) Bifacial PV Array had connected to a Redarc B2B/MPPT Controller, but this had failed so an replacement was required.

12V Option. Fit an MPPT Controller capable of at least 50A and potentially 70A.

24V Option. Fit an MPPT Controller capable of at least 25A and potentially 35A.

| Voltage | Pros | Cons |

| 12V System | Higher Cost due to Higher Output Controller | |

| 24V System | Lower Cost due to Lesser Output Controller |

3) Inverter

There was an existing 24V 1600W Modified Sine Wave Inverter that came with the Horsebox. This was servicable and a good brand (Waeco).

| Voltage | Pros | Cons |

| 12V System | Need to buy another Inverter to have 240V off-grid electrics Less efficiency from 12V supply Heavier Cable to supply cable | |

| 24V System | No cost to use existing Inverter Lighter Cable to deliver same power |

4) 12V Leisure Electrics

There was the various array of 12V Electrics to be serviced - Fridge, Lights, etc.

| Voltage | Pros | Cons |

| 12V System | No changes required | 12V Supply Voltage varies on battery level |

| 24V System | 12V Voltage level can be more consistant | Need to install a DC-DC Converter to provide a 12V supply from a 24V |

Costs of going 24V:

Using a VSR instead of a B2B provides a saving of approximately £200.

The 24V system means a Victron 100/30 is suitable. a 12V System would require at least a 100/50 or even a 150/60 in the Victron range. Using the 100/30 on a 24V system provides a saving of approximately £100 over the 100/50 on a 12V system whilst also providing more capability.

Using the existing 24V Inverter instead of purchasing an equivalent spec 12V Inverter provides a saving of around £200.

Needing to fit a DC-DC Converter suitable to support a Compressor Fit is a cost of around £130

Not needing to buy a device to allow the Starter Battery to charge from EHU and Solar would be a cost saving of around £60

Summary:

Updates and Purchasing Products were required whichever route was taken, but taking the 24V route meant a saving of over £400.

Clearly some of the saving was down to already having a 24V inverter.

The downside to the charging compromise of using a VSR instead of a B2B is mitigated by having a quality Smart MPPT Controller and a decent PV array to 'take up the baton' plus the benefit of getting the same Smart Charging available to the Starter Battery.

System following installation (but before cable tidying & clipping)

Horsebox Systems by David, on Flickr

(Sorry for poor pic. Didn't notice until too late to take another)