wildebus

Forum Member

What's "Tech Neck"? Well, it is like a Red Neck setup but using Technology

I was going to install a Eberspacher Handiwash system in my Campervan, but that requires a wall to mount it on and I will not have any walls in my build - at least not in build 1.0

I do want some hot water though. Currently I just boil a kettle on the hob and to be fair that works pretty well (a 2kW induction hob is VERY fast!). But I also think I should be maximising the solar power which is going to waste when the batteries are full.

Pretty common stuff, but the Tech Neck bit comes in as I don't want to splash out any real money to do this

So 300W immersion heater element bought from Amazon - Aiicioo 12v 300w Heating Element DC Immersion Heater with BSP Thread Submersible Heater for Solar Energy or Wind Turbine: Amazon.co.uk: DIY & Tools

Made a hole in the cap of a spare water container:

Heater in Cap by David, on Flickr

Filled up the container (just a 10L one) in the sink

Hot Water Container by David, on Flickr

And fitted cap

Hot Water!? by David, on Flickr

The angle of the heater is fine and the element is not touching the sides at all. Of course how well the container stands upto the heat is another question, and one reason why I am leaving this in the sink for the testing

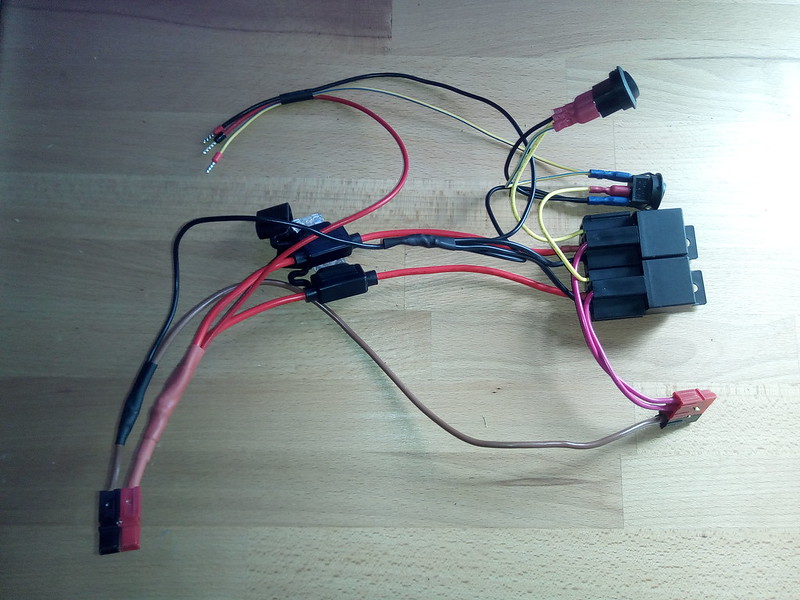

I will also fit the wiring onto a quick-disconnect so it will be easy to remove the container cap. Using an external 30A relay, protected with a fuse and with 4mm Stranded Cable to supply the power to the heater element,

Now the heating ....

One option that some people use is the LOAD terminals on their Solar Controller. Mine is a Victron 100/30 MPPT Controller and only has a virtual LOAD terminal - and I cannot use those as they are used by a USB connection to the Raspberry Pi running Venus GX s/w.

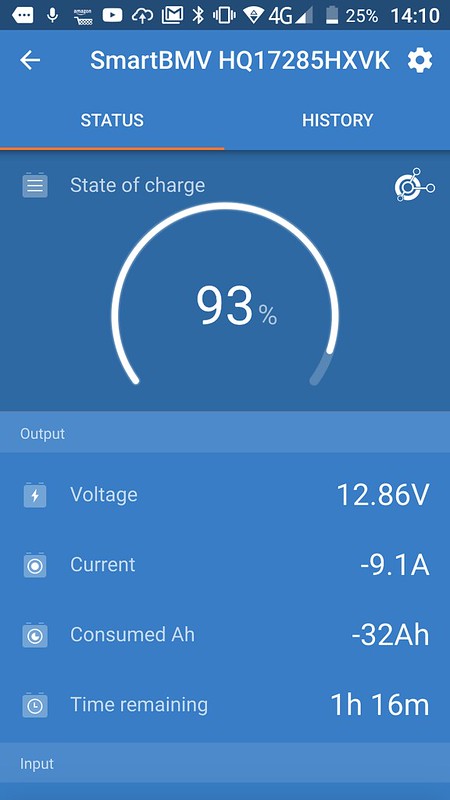

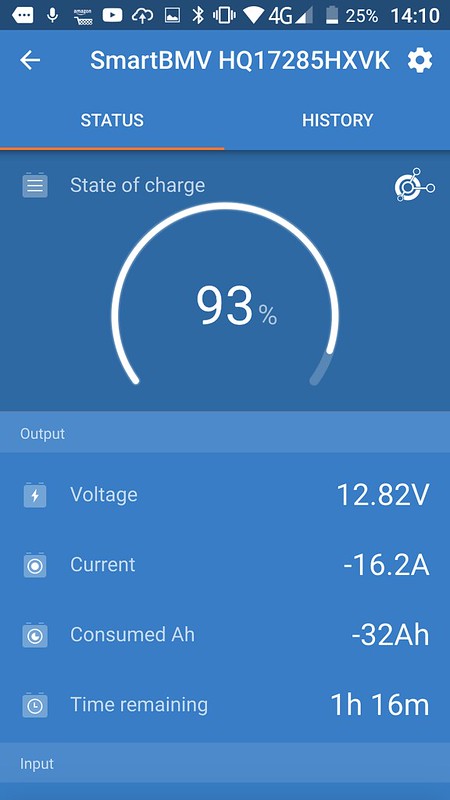

However, the Victron BMV-712 I have has a configurable Relay which I should be able to utilize

BMV-712 Relay Setup by David, on Flickr

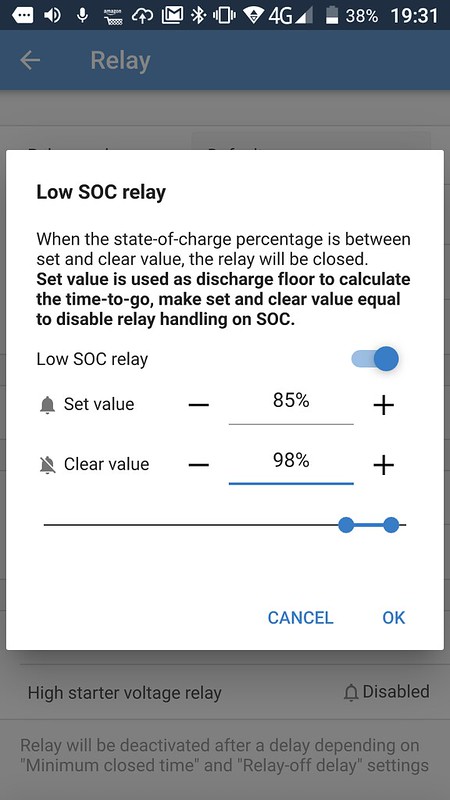

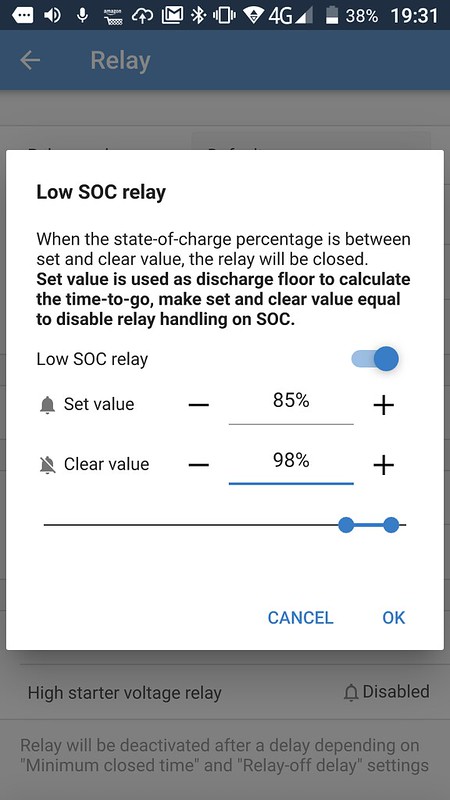

I used the SOC (state of charge) setting to control the relay action. This is primarily designed to be used to kick on a generator when the SOC drops to a certain figure, but of course, I want to turn on the relay when the SOC rises to a certain figure - the opposite action! Luckily Victron provide an "invert relay" option to reverse the standard operation, so this was turned on.

After a bit of testing and playing around to make sure the relay was doing what it was meant to, set it up with the following parameters ..

SOC Settings by David, on Flickr

The description of how it works in the screenshot about is slightly simplified but in essence right.

So when the relay is off, when the SOC hits over 98%, the relay turns on. It then stays on until the SOC drops below 85%. These numbers I kind of plucked out the air to test things out - obviously fine tuning will be required to get them right.

How long will it take to heat up the water? I used this on-line calculator - http://processheatingservices.com/water-heating-time-calculator/ - and it told me to raise the temp of 9L of water by 50C using a 300W heater should take 104 minutes.

the water in the container was around 25C and the relay clicked on at 19:30, at which time I went in for some supper

Came out at 21:00 to check the water and it was a very hot 85C! - so actually just 90 minutes to heat (maybe I only had 8L of water in the container?).

The SOC had dropped from 99.2% to 89.0% - so 10% of the battery used in this time. There was some solar coming in, but of course I had other draws as well, and those two pretty well cancelled each other out.

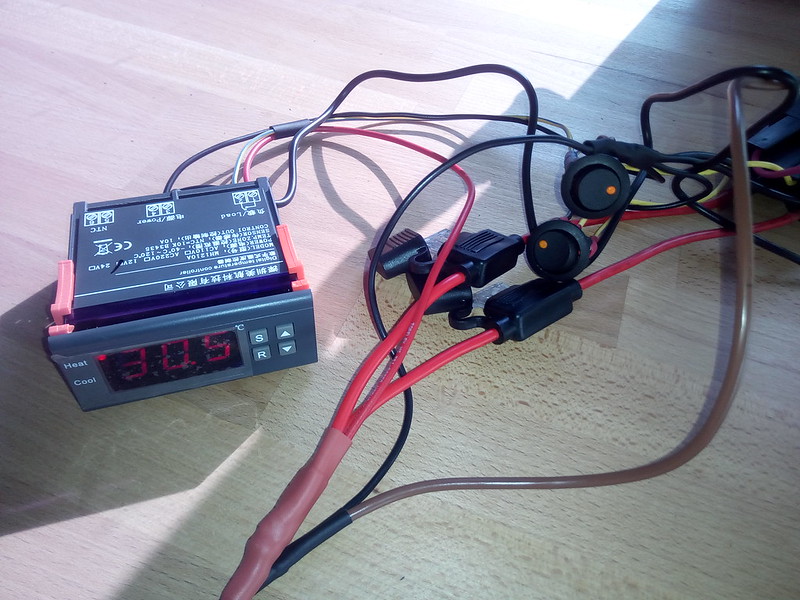

So it looks like heating the water uses 10% of the Battery Array. With the settings I have it will come on during the day (the intention of course!), so when it comes to the relay parameters, it will be more complex than just having a 10% window. The element has no thermostat control either - these are always seperate on Immersion Heater Elements - so I think I will need to add a thermostat control in series to ensure the water does not get too hot (85C is VERY hot of course). Maybe get the same unit as I used on the Fridge Fan - that works well and is good value for money (might need to check if the temp probe is waterproof? can also be taped to the side anyway).

I can also if need be split the 300W element into two 150W elements and just run a single one at lower power to have less draw-down on the battery and so be much more solar-driven during the day.

Will repeat the test tomorrow in main 'solar' hours and with a much tighter SOC range and see what happens.

So this is the start of my Tech Neck hot water - an alternative to having a container of water placed in the sun to warm up

Total cost so far is around £26 as I reused some bits and pieces I had already.

I'll update this as the setup progresses and enhances.

I was going to install a Eberspacher Handiwash system in my Campervan, but that requires a wall to mount it on and I will not have any walls in my build - at least not in build 1.0

I do want some hot water though. Currently I just boil a kettle on the hob and to be fair that works pretty well (a 2kW induction hob is VERY fast!). But I also think I should be maximising the solar power which is going to waste when the batteries are full.

Pretty common stuff, but the Tech Neck bit comes in as I don't want to splash out any real money to do this

So 300W immersion heater element bought from Amazon - Aiicioo 12v 300w Heating Element DC Immersion Heater with BSP Thread Submersible Heater for Solar Energy or Wind Turbine: Amazon.co.uk: DIY & Tools

Made a hole in the cap of a spare water container:

Heater in Cap by David, on Flickr

Filled up the container (just a 10L one) in the sink

Hot Water Container by David, on Flickr

And fitted cap

Hot Water!? by David, on Flickr

The angle of the heater is fine and the element is not touching the sides at all. Of course how well the container stands upto the heat is another question, and one reason why I am leaving this in the sink for the testing

I will also fit the wiring onto a quick-disconnect so it will be easy to remove the container cap. Using an external 30A relay, protected with a fuse and with 4mm Stranded Cable to supply the power to the heater element,

Now the heating ....

One option that some people use is the LOAD terminals on their Solar Controller. Mine is a Victron 100/30 MPPT Controller and only has a virtual LOAD terminal - and I cannot use those as they are used by a USB connection to the Raspberry Pi running Venus GX s/w.

However, the Victron BMV-712 I have has a configurable Relay which I should be able to utilize

BMV-712 Relay Setup by David, on Flickr

I used the SOC (state of charge) setting to control the relay action. This is primarily designed to be used to kick on a generator when the SOC drops to a certain figure, but of course, I want to turn on the relay when the SOC rises to a certain figure - the opposite action! Luckily Victron provide an "invert relay" option to reverse the standard operation, so this was turned on.

After a bit of testing and playing around to make sure the relay was doing what it was meant to, set it up with the following parameters ..

SOC Settings by David, on Flickr

The description of how it works in the screenshot about is slightly simplified but in essence right.

So when the relay is off, when the SOC hits over 98%, the relay turns on. It then stays on until the SOC drops below 85%. These numbers I kind of plucked out the air to test things out - obviously fine tuning will be required to get them right.

How long will it take to heat up the water? I used this on-line calculator - http://processheatingservices.com/water-heating-time-calculator/ - and it told me to raise the temp of 9L of water by 50C using a 300W heater should take 104 minutes.

the water in the container was around 25C and the relay clicked on at 19:30, at which time I went in for some supper

Came out at 21:00 to check the water and it was a very hot 85C! - so actually just 90 minutes to heat (maybe I only had 8L of water in the container?).

The SOC had dropped from 99.2% to 89.0% - so 10% of the battery used in this time. There was some solar coming in, but of course I had other draws as well, and those two pretty well cancelled each other out.

So it looks like heating the water uses 10% of the Battery Array. With the settings I have it will come on during the day (the intention of course!), so when it comes to the relay parameters, it will be more complex than just having a 10% window. The element has no thermostat control either - these are always seperate on Immersion Heater Elements - so I think I will need to add a thermostat control in series to ensure the water does not get too hot (85C is VERY hot of course). Maybe get the same unit as I used on the Fridge Fan - that works well and is good value for money (might need to check if the temp probe is waterproof? can also be taped to the side anyway).

I can also if need be split the 300W element into two 150W elements and just run a single one at lower power to have less draw-down on the battery and so be much more solar-driven during the day.

Will repeat the test tomorrow in main 'solar' hours and with a much tighter SOC range and see what happens.

So this is the start of my Tech Neck hot water - an alternative to having a container of water placed in the sun to warm up

Total cost so far is around £26 as I reused some bits and pieces I had already.

I'll update this as the setup progresses and enhances.